Our cosmos

Applications

Innovations

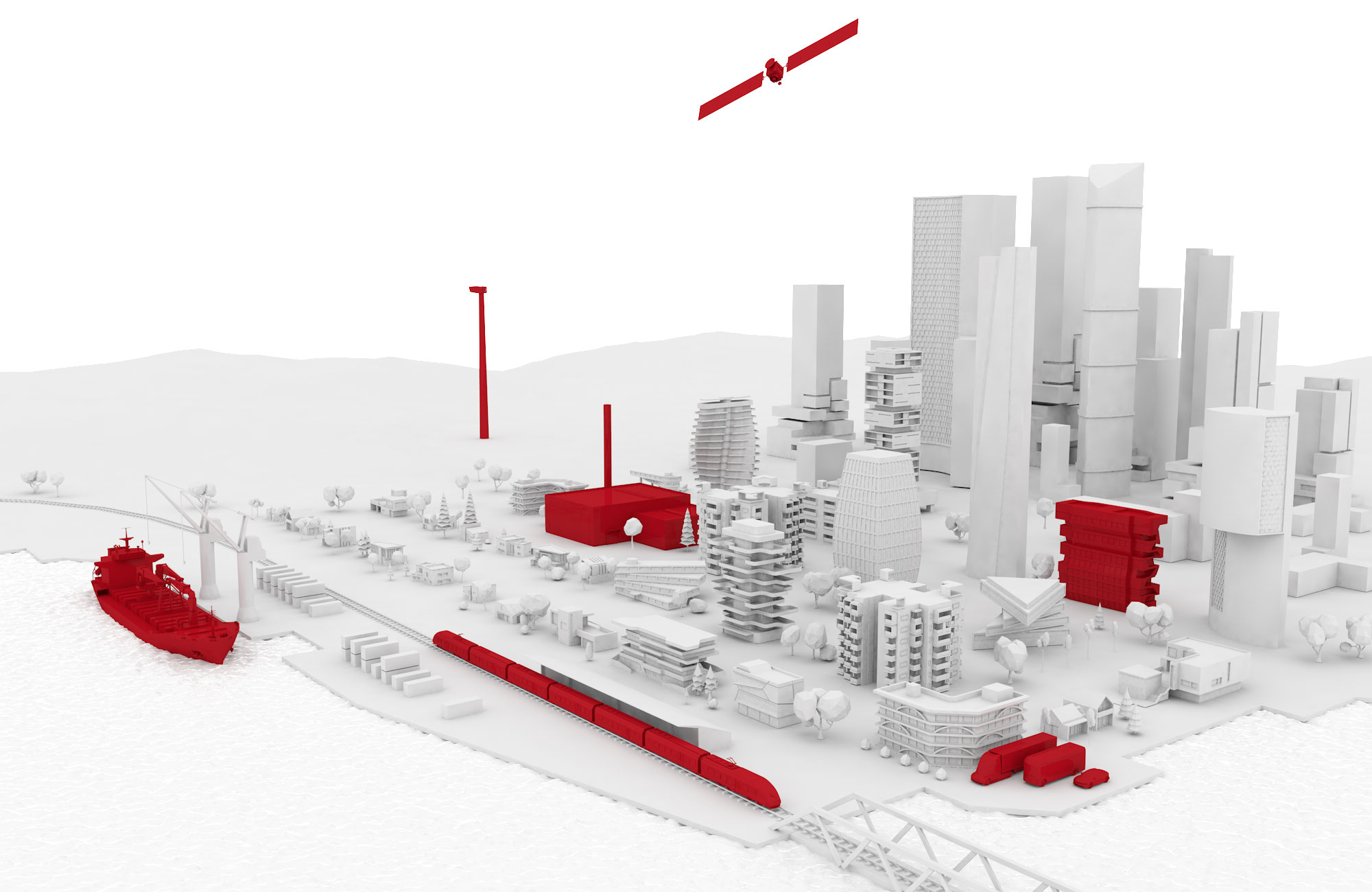

Integrated Solutions for Intelligent and Interactive Systems

Integrated Solutions for Intelligent and Interactive Systems

The future starts now

Applications Sensors and actuators efficiently integrated

Innovations Sustainable solutions for you!

Our know-how to give you a technical edge We can help you boost the productivity of your plants and ease the burden on accompanying processes.

Digital MiniCODER among the "Product of the Year" winners

Our digital MiniCODER achieved the third place in the drive technology category of the "Product of the Year" competition. The voting was initiated by the German trade magazine Computer&Automation. 96 products in twelve categories were up for election.

Position displays: Simplify manual adjustment processes

Lenord+Bauer’s SeGMo-Assist digital position display simplifies manual adjustment processes. It can be combined with the GEL SEROT external rotary sensor, which is suitable for mounting in hard-to-reach locations thanks to its hollow shaft and compact design.

Sensors for maritime combustion engines and electric motors

Lenord+Bauer has published the new brochure “Motion sensors for maritime applications”. These encoders are used for speed control or positioning in cruise ships, special ships and tankers. They also detect rotation angles in pod drives and positions in sluice gates. Furthermore, they are used in gearbox and winch applications. The company provides sensors with ATEX…